I love the idea of biomimicry: the art of solving engineering problems by observing nature. If you have ever used a piece of velcro, then you have used something invented through biomimicry.

Japanese bullet trains (or Shinkansen) are also famous for using biomimicry, copying features of Owls, Adelie Penguins and KingFishers to dramatically reduce noise and vibration and resulting in their ability to travel at remarkable speeds.

But do you know that IBM also once embraced biomimicry? Thats right…. in 1974 the B in IBM also stood for BEEHIVE!

This all started in the late 1960s when IBM began developing something they had never tried before: a genuine robotic tape library. Developed at IBM’s Lab in Boulder, Colorado, the developers concluded the most efficient shape to store data cartridges was in a honeycomb array. The product they developed was code named Comanche and was announced as the IBM 3850 Mass Storage System (MSS) in October 1974.

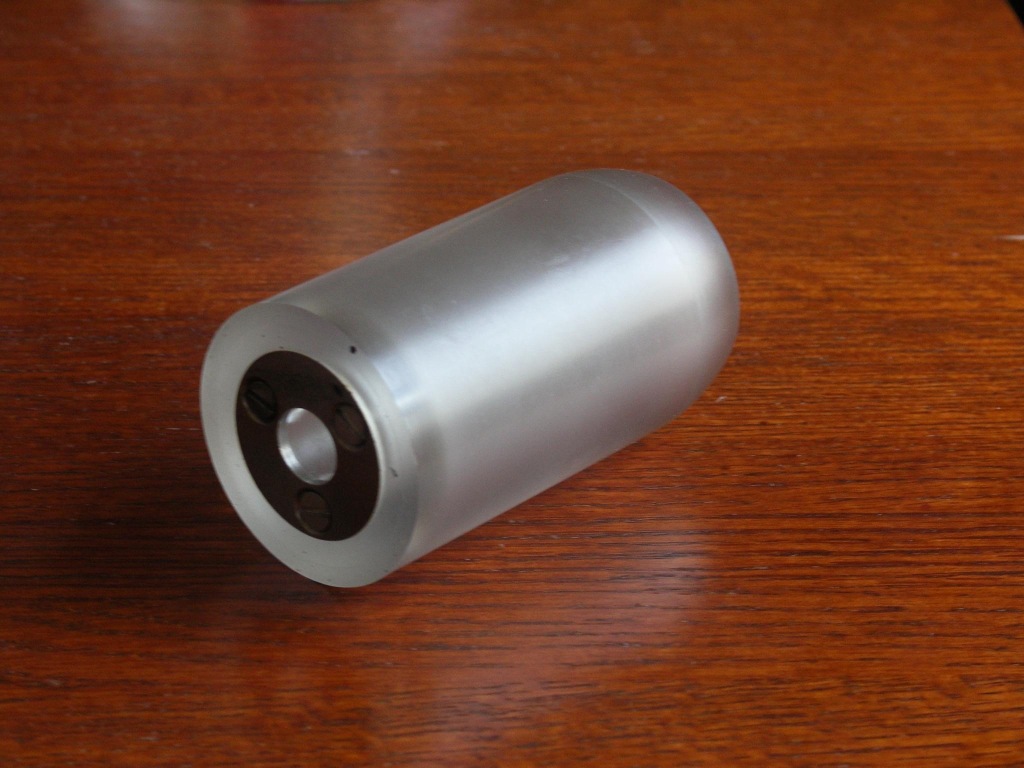

It contained a huge number of firsts for IBM. For one thing it used a whole new circular tape cartridge that looked like this:

Each of these bullet shaped cartridges were two inches in diameter and four inches long, holding a spool with 770 inches of tape. The cartridges could hold 50 MB and were read diagonally. They were designed to be robotically fed into a whole new tape drive known as a DRD or “Data Recording Device” – pronounced “DiRD”. These drives were going to be called a “Tape Recording Device”, but that was changed when the developers starting shortening that to “TiRD”.

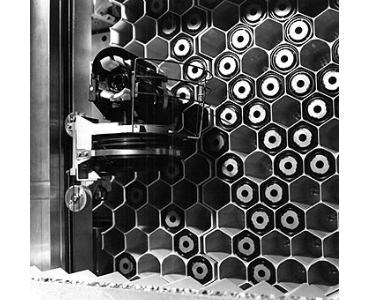

The carts were stored in a honeycomb library known as an IBM 3851 with two accessors (robots). Given the time period, it is very hard to find decent photos (or videos) but here are a couple of the accessor and the honeycombs:

This product was packed with firsts for IBM:

- First robotic tape library (with not one but two accessors!)

- First circular tape cartridge

- Brand new tape drive design

- Brand new Control unit (the IBM 3830-003)

- Disk virtualisation using automated tape. Thats right, this thing could take two 50 MB tape carts and use them to emulate a 100 MB removable disk pack. This meant the tape library could appear to the mainframe as a mountain of removable disk packs, with up 16 online at any time. This feature was phenomenal and users loved it because it gave them what seemed like unlimited storage for huge batch jobs and testing new apps with copied production data.

And in case you are unimpressed by 100 MB of disk space, compare the relative sizes (for the time), remembering those little carts were just four inches long….

Now at this point you may be thinking, wow this sounds fantastic – how come I have never heard of it?

The problem was that list of ‘firsts’: there was simply too much new technology all in one product. The MSS was a master class in complex and demanding microcode (firmware) and there was way too much dependence on exact mechanical performance. Unless the IBM Engineers who installed and maintained it were truly expert at their job, way too many things could go wrong. The pickers had to be very well aligned to get the cartridges in and out of their honeycomb positions. Different sections of honeycomb could be imperfectly aligned when assembled together, or worse the honeycomb itself could be distorted (or badly manufactured). If a cartridge was forced into an undersized honeycomb position it could cause severe damage to the machine and destroy the data in the cartridge. The accessors were also notorious for occasionally crashing into badly inserted carts or even dropping and losing carts.

War stories about the MSS abound, such as the attempt to detect badly sized cells using a slightly over-sized test cart. A library microcode engineer brought one to a troubled install at the Johnson Space Center in Texas. They began the test routine and within minutes it found a badly shaped cell. The accessor strained and strained to insert the test cart into the bad cell, trying so hard it tripped not only its circuit breaker, but a whole series of upstream circuit breakers, powering off the whole NASA data centre. A classic ‘what have you done’ moment.

Another amusing story concerns the photoshoot for when the MSS was featured on the cover of the 1974 IBM Annual Report. The position of the accessors for the cartridges was based on light-based indexing. If anything went wrong they would park themselves in garages at either end of the aisle. The photographer was shooting at an actual customer location (Montgomery Wards Data Center in Lenexa, Kansas) and needed more light to capture the honeycomb, so he instructed the account rep to get inside the machine with an auxiliary flash. As soon as the flash went off, the accessor concluded it was broken and headed for it’s garage, moving at five mile per hour. The salesman’s comment:

“I never realized how fast 5 mph could seem until I saw that thing headed for my belly-button.”

He was not injured, but the unexpected accessor crash literally caused a system outage (oops).

An example of IBMs struggle to master the microcode was that while there were two accessors, only one could be active at a time. IBM could never get the two to work simultaneously, as they would sometimes violently crash into each other. IBM only managed to finally achieve this feat more than 20 years later in a different product, the IBM 3584, with a feature we called dancing robots, or officially “dual active accessors”.

Another problem with the product was IBMs obsession with moving things and people around (IBM at the time truly stood for “I’ve been moved”). Having developed and initially manufactured the MSS in Boulder, in 1976 they moved MSS manufacturing to San Jose, California to make more space in Boulder to manufacture IBMs Copiers. And having moved the MSS to San Jose, in 1979 they then moved it to Tucson Arizona to make more space in San Jose for disk manufacturing. And then having moved it to Tucson, they then decided to cease manufacturing completely at that site and moved MSS manufacturing back to San Jose. Each move lost experienced staff and resulted in an overall loss of “tribal knowledge”.

So things did not go well for the MSS. In fact the big hint that things were not going well was when in 1984, IBM came out with a whole new 200MB cartridge (for the new IBM 3480), that was…. square! It clearly could not be used in the MSS.

At its peak there were only 350 MSS subsystems installed world wide (peaking at 274 in North America). Rapid advances in disk sizes and disinterest inside IBM, all meant the end for the humble honeycomb robot. It was withdrawn in August 1986 (without replacement) and maintenance was stopped in 1991 (which was quite fast for those days).

The MSS is now best remembered by IBM Collectors, who love to show off (and sometimes also sell) their souvenir MSS parts. You can see from left to right a data cartridge that has been opened, a green customer engineer test cartridge and a yellow system engineer test cart, as well as a honeycomb segment.

In terms of classic IBM recycling, the cartridges came in plastic trays, which were perfect to put in your drawers to sort out small bits of stationary. It is quite possible people are still using these, with no clue where they came from or what they were originally for:

Want to read more? Check these out:

https://www.ibm.com/ibm/history/exhibits/storage/storage_3850.html

Started following your blog way back in the day when I was involved in IBM storage. Since then I wound up working for – and getting laid off from – IBM. Glad to see you’re getting active again and loving the stories, although some of the details of dumb things IBM has done hit a little too close to home now. :)

Glad you liked the post. The next one is a lot of fun and details far more success.

Anthony, your ability to write a hilarious blog post is absolutely legendary!

Thank you so much!

I spent 6 years looking after a Fujitsu “Compatible” MSS at the Bureau of Stats in Canberra. The Japanese had copied the IBM design but had improved it, once it was bedded down, it was quite a reliable piece of kit. That said, it did provide me with some of the most “Interesting” problems that I saw in 40 odd years in the industry. Most of these were mechanical, but there was one micro-code problem. The factory sent down 4 guys to fix it, they weren’t engineers, but the designers of that part of the system. The fix was one line of code which was ceremoniously handed to me to button into the disk controllers.

I still have a cartridge in the bookshelf in my office as a souvenir of those days.

Thats amazing. I had no clue that existed. Thanks for sharing

Anthony – just discovered your blog today. posted my story related to the 3495 post. Loved that blog entry. thanks!

I also had an encounter with the IBM 3850. A couple of years before the 3495 and my days on what eventually became known as DFSMSrmm, I had been an “industrial trainee” working for a year for IBM between my 2nd and 3rd years of university.

One of my jobs was to drain the MSS installed at the IBM Warwick data center of its data and cartridges. So, I had this list of data sets and owners and walked around the building all day trying to get people to let me know the disposition of their data. This was before email – we did not yet have Profs (OfficeVision VM). I don’t recall too much, but I remember my mentor, Ed Watson telling me that the data was written diagonally on the cartridge in order to one cylinder or track of data in each row of data on the cartridge. That limitation meant that the engineers had to invent a method to diagonally stripe the data. Pretty smart guys I guess.

Now, I regret to this day not getting any of the cartridges. I think I had one at one time and threw it out. I didn’t save a single one. So if there is someone out there feeling benevolent, I’d be interested in having one as a dust gatherer for my desk!

My Favorite machine. Had three at Merrill Lynch NYC. Ah the challenge of upgrading code and drive Skew adjustment. Still have a couple of CE tapes but recycled a cell block.